PLASTIC MOLD DESIGN

Main Stages of Plastic Mold Design

Stage 1: Manufacturability and Feasibility Analysis

This initial phase involves close collaboration among design engineers, tooling engineers. The team evaluates product specifications, mold functionality, material selection, operational constraints, and potential design improvements.

Special attention is given to part geometry and tolerances that could affect mold performance—such as risk of weak steel sections or the need for complex features like lifters, slides, or unscrewing mechanisms.

The physical and chemical properties of the selected resin are analyzed to guide appropriate mold steel selection and optimize cooling system design. Mold flow analysis is conducted to determine the ideal gate type and location, as well as proper venting positions.

A comprehensive manufacturability review ensures adherence to best practices in plastic part design and incorporates critical tooling details for maximum robustness. Tooling specifications are finalized, and suppliers for standard components are qualified.

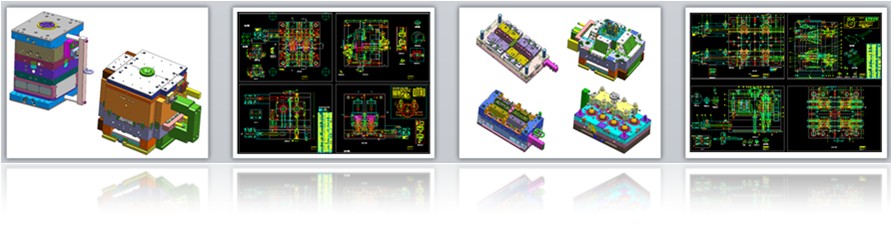

Stage 2: Mold Design Development

Preliminary 2D layouts and 3D models are created to define parting lines, cavity layout, and core/cavity steel dimensions. Once reviewed and approved, the design progresses to detailed engineering, including ejection systems, cooling channels, and structural components.

Stage 3: Final Design Specification

Final mold design specifications are released to the tool builder for construction. Any necessary refinements are made in-house with a focus on manufacturability, precision, and adherence to critical dimensional requirements.

Stage 4: In-House Tool Qualification and Initial Sampling

Once the mold is received, a robust molding process is established in collaboration with the manufacturing team. Scientific molding principles are applied, including the use of cavity pressure transducers to accurately capture fill profiles and optimize process stability.

Recommended processing parameters are documented, and initial sample parts are produced and inspected for quality and conformance. These samples undergo rigorous evaluation to ensure they meet design and performance criteria.

Stage 5: Final Tool Adjustments and Production Readiness

Based on sample results, any required tool modifications or process adjustments are implemented. The mold is verified for full functionality, and the finalized process is thoroughly documented to enable quick setup and repeatability in future production runs.

Final sample parts are produced and submitted to the customer for approval. Upon customer sign-off, the mold is released for full-scale production.

Will provide steel certification and heated treatment certification for full-hardened steel. The steel can be from Gröditz, ASSAB , LKM, BÖHLER, SSAB, FINKELDAIDO, HITACHI .......

Will choose mold components that easy to buy in different overseas country. Below are some of our components suppliers as HASCO, DME, Meusburger, DAIDO, CUMSA, LKM, MISUMI, PUNCH, PARKER, MERKEL, HP SYSTEM, Stäubli......

And hot runner system will be as HRS, HUSKY, MOLDMASER, INCOE, SYNVENTIVE, YUDO, männer, GÜNTHER, THERMOPLAY, MASTIP, HOTSYS.......